By now, everyone knows that plastics are a problem. But besides recycling packages and skipping the straws, what can we actually do to challenge the dominance of plastic in our lives? Andrew Falcon, CEO of Full Cycle Bioplastics, has one important solution. “It’s about changing our perspective to stop thinking about materials as waste, and instead think about all materials as resources,” he explains to Musings. Full Cycle Bioplastics is one of the most innovative players we’ve encountered working in the circular economy. They produce “nature’s plastic” or PolyHydroxyAlkanoates (PHAs). It’s basically bacteria fat, but it also happens to functions as a bio-based and biodegradable plastic alternative. Unlike the oil-based plastics we’re used to using, PHAs don’t contribute to greenhouse gas emissions, don’t pollute the oceans and don’t contain toxic chemicals. In other words, it transforms low-value waste into a high-value product without negative consequences. In fact, Falcon suggests, using bioplastics can even be a net boon for companies. Full Cycle Bioplastics is soon opening its pilot facility, which will convert food waste into compost and PHAs for re-use; Falcon knows this is a “critical” step towards offering up their technology more broadly and providing the sustainable plastic alternative our planet needs. Turns out bacteria have a lot to offer us, if we’re ready to buy in.

But besides recycling packages and skipping the straws, what can we actually do to challenge the dominance of plastic in our lives? Andrew Falcon, CEO of Full Cycle Bioplastics, has one important solution. “It’s about changing our perspective to stop thinking about materials as waste, and instead think about all materials as resources,” he explains to Musings. Full Cycle Bioplastics is one of the most innovative players we’ve encountered working in the circular economy. They produce “nature’s plastic” or PolyHydroxyAlkanoates (PHAs). It’s basically bacteria fat, but it also happens to functions as a bio-based and biodegradable plastic alternative. Unlike the oil-based plastics we’re used to using, PHAs don’t contribute to greenhouse gas emissions, don’t pollute the oceans and don’t contain toxic chemicals. In other words, it transforms low-value waste into a high-value product without negative consequences. In fact, Falcon suggests, using bioplastics can even be a net boon for companies. Full Cycle Bioplastics is soon opening its pilot facility, which will convert food waste into compost and PHAs for re-use; Falcon knows this is a “critical” step towards offering up their technology more broadly and providing the sustainable plastic alternative our planet needs. Turns out bacteria have a lot to offer us, if we’re ready to buy in.

What sparked your mission to tackle plastic pollution by creating environmentally-friendly “bioplastic?”

After spending the early part of my career involved in traditional plastics and packaging, I came to better understand the tremendous unintended consequences of those industries and recycling systems. My increased awareness coincided with fatherhood and two lovely children, and I found that my perspective and priorities had shifted dramatically. I wanted to be a part of a sustainable solution for materials and packaging, and to stop contributing to a linear industrial system that, if left unchecked, will damage the planet irreparably.

What exactly is bioplastic? And how is it created?

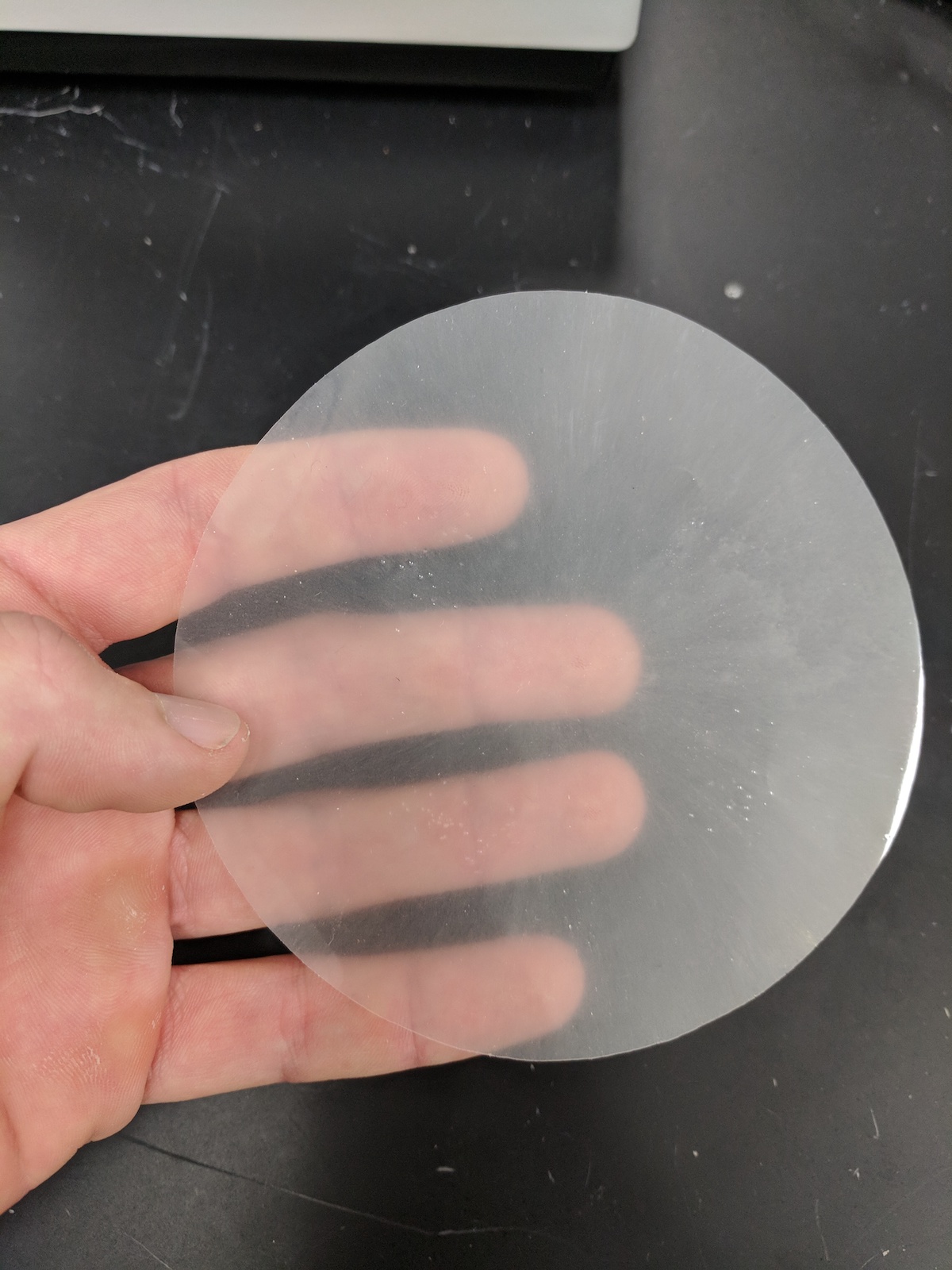

In the case of Full Cycle Bioplastics, our material is made from renewable organic resources and degrades harmlessly at the end of life. In that sense, it’s both “bio-based” and “biodegradable,” which represents the best of both worlds when talking about bioplastics.

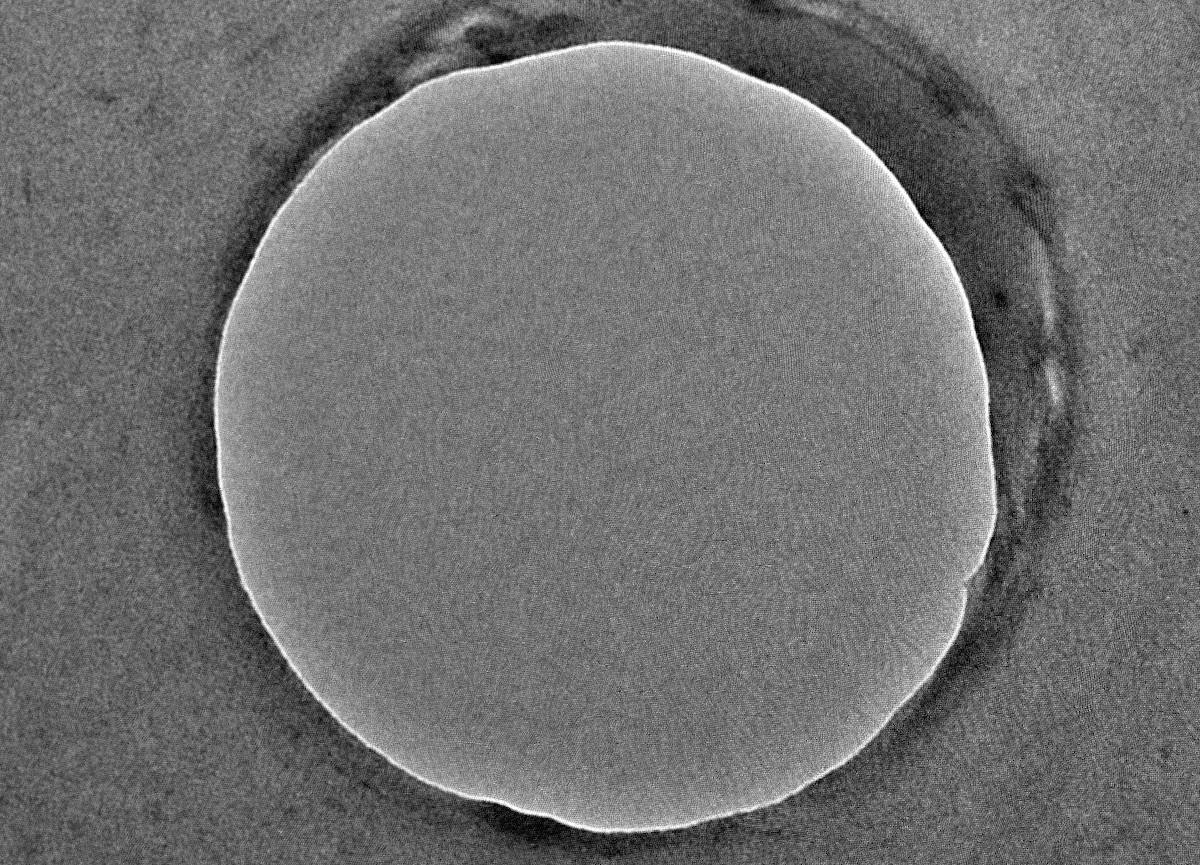

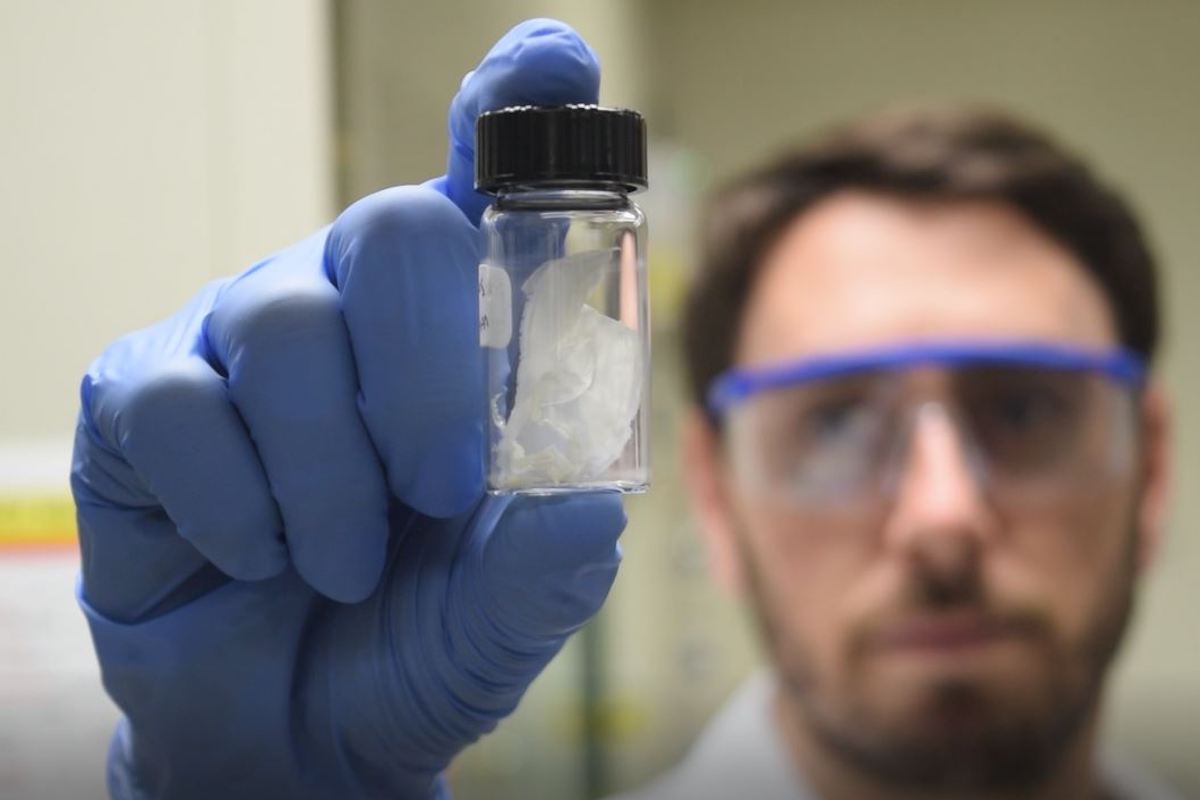

Specifically, we produce PolyHydroxyAlkanoates (PHAs), which are a family of naturally-occurring polymers made by bacteria. Our non-GMO bacteria eat a wide variety of organic waste (such as un-recyclable food waste), turning it into PHA that they store internally and consume as energy when they don’t have other food to eat. PHA is actually bacteria fat!

Some people call it “nature’s plastic” because you can extract PHA and use it as an alternative to many typical oil-based plastics. But because it’s made naturally and is already a part of the earth’s existing biome, it has extremely attractive degradation properties at end-of-life. In fact, different types of PHAs have been certified as biodegradable in anaerobic, soil, freshwater and marine environments, as well as compostable in both home and industrial composting facilities.

Unlike most oil-based alternatives, PHA at minimum “does no harm” once its useful life is over. In the case of Full Cycle’s technology, that end-of-life benefit goes one step further: because PHA itself is organic material, if you return it to us after use (as part of an organic waste recycling system, for example), we can use it as raw material to make virgin PHA again—a circular, regenerative material solution.

Why is regular plastic such a huge problem and how are your compostable alternatives a solution?

Regular plastics are ubiquitous—it’s almost impossible to imagine daily life without them, and there is a reason for that. Plastic is economical, and its functional properties lend it to a wide range of applications. But unfortunately, oil-based plastics were not created with end-of-life utilization in mind. The growth of the plastics industry has not seen a commensurate growth in systems for re-use or recycling. Plastics are hard to recycle, are growing in volume rapidly and are leaking at a tremendous rate into the environment and our oceans. What many people aren’t yet grasping is that we cannot recycle our way out of the current problem. A new and improved system needs to be created.

There will always be some plastic products that are either technically impossible or not economically viable to recycle. Many of those products are also often contaminated with organic material (like many types of food packaging). This is a portion of the market that would benefit from alternative materials and would be less damaging if they were compostable and part of an organics recycling loop.

Organic waste recycling infrastructure is increasingly being recognized as an essential component of holistic, sustainable materials systems, which we are huge advocates for. And we believe our technology—which makes high-value PHA bioplastic out of low-value organic waste inputs—could be a big part of helping catalyze that infrastructure investment. Basically, we would be making the recycling of organic waste more profitable for companies.

What has been the biggest challenge  in developing this product and getting people to buy into its potential? What has been the easiest sell?

in developing this product and getting people to buy into its potential? What has been the easiest sell?

Let’s start with the easy part: everyone is enthusiastic about the idea of a circular materials loop for organic waste and plastics. Consumers and companies have been screaming for sustainable material alternatives for decades.

But this is a new material technology that is expensive to demonstrate, and to scale. We have a much deeper and wider “valley of death” than a typical startup focused on software or the next big app. Access to capital and partners to showcase successful operation of our system is essential, as is a better understanding of the long-term need.

Full Cycle Bioplastics is part of the growing movement towards a more “circular economy.” What does that mean, and why is it a critical part of the fight against climate change?

We are huge fans of the circular economy, and would particularly point out the tremendous work the Ellen MacArthur Foundation has done to bring this concept to light. To us, the circular economy is about efficient use and re-use of materials, whether technical or biological, and about systems that are designed to keep material circulating. It’s about changing our perspective to stop thinking about materials as waste, and instead thinking about all materials as resources.

What the circular economy is not is a continuation of the linear “take-make-waste” paradigm that underpinned growth in the consumer economy over the past 50+ years. Food and plastic waste contribute to greenhouse gas emissions, climate change and pollution of our ecosystems, and is among the largest environmental challenges facing the planet.

As a CEO and inventor, what excites you about being in the business of creating sustainable solutions? What concerns you?

I am constantly amazed and buoyed by growing awareness of environmental challenges, and the increasing conviction and willingness of everyday people to take action to drive change. We see the power of consumer sentiment in catalyzing policy and business shifts, and we should continue to harness this momentum to create new and better systems for the planet. Urgently! Today!

At the same time, the issues we’re addressing are complex, intertwined, system-level challenges. The reality is that there is not a single solution. What might work in the U.S. may be impractical in emerging markets. It’s important to remain open and supportive of new and different approaches. If we’re overly dogmatic, we can let the quest for a perceived perfect get in the way of real, practical good.

What’s your advice to the casual consumer who wants to phase out harmful plastic usage from their day-to-day life and begin replacing it with materials like your bioplastic?

Be aware. Educate yourself. Reduce and eliminate your use of plastics (especially single-use plastics) as best you can. Be open to new packaging or material alternatives. While that approach can feel incremental, one of the biggest levers we have as individual consumers is to actively encourage new and innovative systems by voting with our wallets!

And when it comes to plastics and packaging specifically, I would also remind people not to forget the positive impact that can come from compostable materials and organic material recycling.

What’s next for Full Cycle Bioplastics?

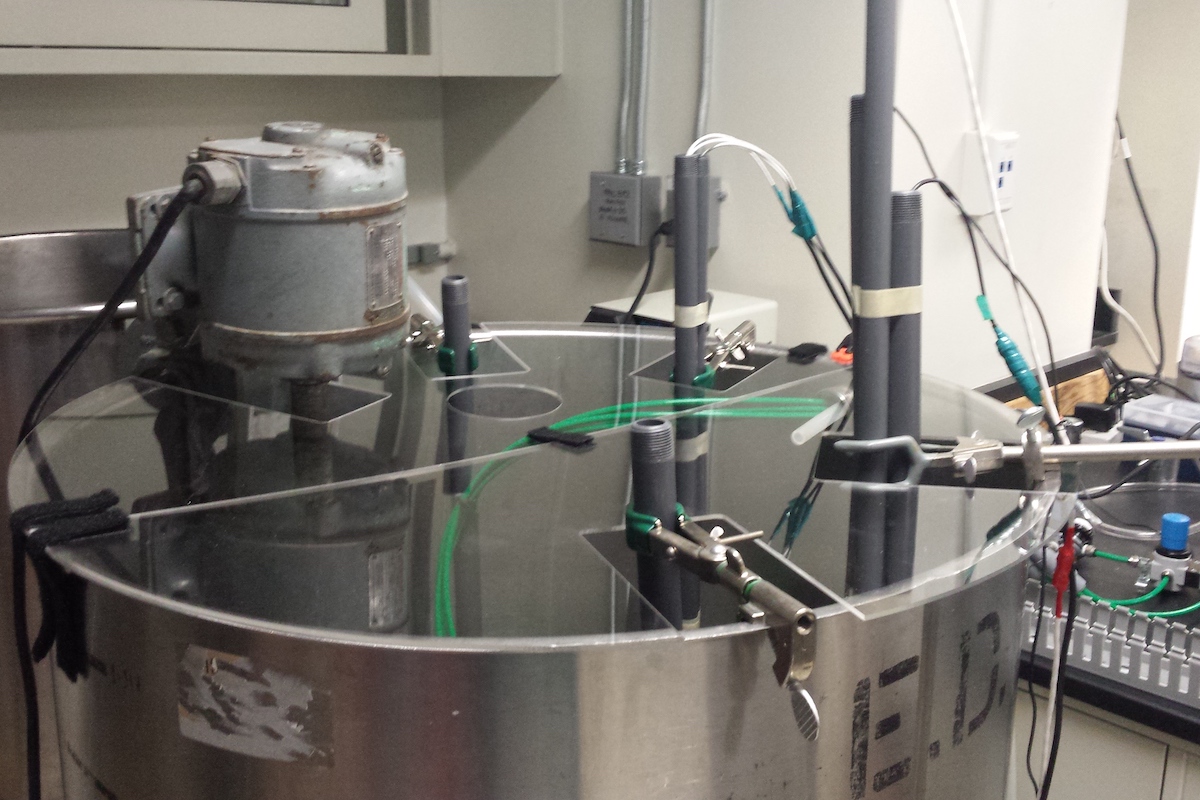

The world’s first closed-loop food-waste-to-PHA facility. Our pilot facility takes food waste and converts it into either compost for use with local farms who supply them produce, or PHA bioplastic for use in their internal food service operations. Demonstrating this circular model in a real-world operating environment will help us scale and showcase the power of our solution.