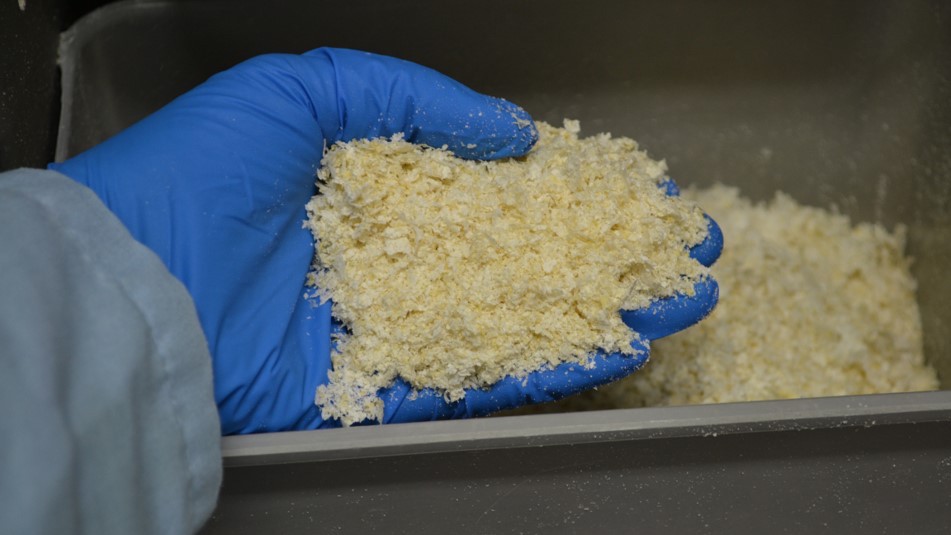

Okara Flour

If food waste were its own country, it would be the third highest greenhouse gas emitter behind China and the U.S. Sumit Kadakia, Co-Founder of Renewal Mill, is tackling this huge environmental issue by turning food manufacturing byproducts into nutritious, viable foods. The company’s first project, okara, the “soy pulp” by-product of soy milk and tofu production, can be dehydrated and turned into a high protein, high fiber flour that both reduces waste and offers nutritional value. The husband-and-wife team at Renewal Mill has similar plans for grapes used in wine making, and almond hulls. Kadakia states of their mission, “if we succeed, we can take large percentage points off the amount of food waste in the U.S.”

When did you realize that food byproducts were being put to waste in the food production process?

We first learned about the struggles food manufacturers face with byproducts when we met Minh Tsai, the founder of Hodo Soy, at a talk at Yale in the spring of 2016. We were both Masters students at the School of Forestry and Environmental Studies and had focused our education, research, and professional efforts up until that point on crafting strategies for low-carbon sustainable development. We knew that food was important to this equation but we didn’t understand the true impact of inefficiencies in our food system until we heard Minh’s story. As an artisanal tofu maker, Minh recognized the value of both tofu and the byproduct, okara (soy pulp in Japanese). He was dissatisfied with needing to dispose of okara or give it away for animal feed. We started to look at the problem posed by okara and soon found that Minh’s issues were shared across almost all food processors.

What are other areas that you feel still need addressing to decrease food waste?

Most food waste occurs in residences and so we are supportive of any effort that helps individuals be more conscious in their purchasing and consumption of food. We’re also particularly supportive of efforts to change the way that grocery stores operate, and hope that outlets such as the Daily Table in Boston drive real changes in eliminating sell-by dates and overstocking. There is one aspect of food waste which is rarely discussed: the public health implication of the foods that we discard. Over 97% of Americans are deficient in fiber, while in contrast 97% of Americans get enough protein. This fiber deficiency is a key driver for increased rates of obesity, heart disease and diabetes. Fiber is often stripped out of our food during processing and so it’s important to devise unique and innovative solutions to bring this fiber back to our plates.

So you started with making okara from soy pulp. How did that idea come about?

Dried Okara Flakes

Okara is the Japanese name for soy pulp. It means “honorable husk.” We like this translation of pulp because of the respect that it offers one of the most nutritious foods.

Are there other companies that are doing this as well?

Renewal Mill is the first company to create a platform process that enables any food manufacturer to find a complete sustainable solution for all of their clean, nutritious, unused food streams. There are companies and organizations that have formed to promote material reuse focused on singular products, several of which we are very excited about! For example, Vegea is creating leather from grape skins – an innovation that will hopefully one day help to reduce total leather consumption.

What was the progression of your additional products?

We are currently working with two additional byproducts both from the creation of plant-based milk and plant-based meat. Preventing environmental degradation is built into the DNA of these companies, motivating them to make their process achieve as light of a carbon footprint as possible.We’re excited to be helping them realize this vision.

Renewal Mill Co-Founder Claire Schlemme

You participated in Food System 6’s first cohort. What was that experience like and what were your takeaways?

We immensely enjoyed our experience in FS6. As new transplants to the San Francisco, we felt lucky to have the community of FS6 to introduce us to the sustainable food movement in the Bay Area. We were continually inspired and challenged by the other entrepreneurs who were similarly working

on implementing solutions at the nexus of food and the environment. It was interesting to see the different problems in the food system that motivated the participants and exciting to follow their progress toward achieving change. Most importantly, we felt fortunate to receive guidance and support from the founders of FS6, Paul Matteucci, Renske Lynde, Sarah Williams and Peter Herz. They are all brilliant and opened several doors (and continue to do so) for us.

How is utilizing food byproducts closing gaps left in the food system?

Unfortunately, our food system is quite inefficient. Within our current structure, an estimated 40 percent of the food produced in the US is never consumed. This is a stark statistic particularly in the face of the fact that 1 in 7 Americans is considered food insecure. And food waste is a key climate change driver: globally, food waste is responsible for greenhouse gas emissions rivaling those of the top two emitters:

Renewal Mill’s Okara Flour

China and the US. Waste occurs across the entire food supply chain from the farm to our refrigerators. At each of these stages in production, a reduction in waste means greater efficiency in our food system. We are specifically targeting byproducts from the manufacturing phase because these products are already food-safe and relatively concentrated, two factors that make downstream processing simpler. By building the bridges between food manufacturers and consumers, we are helping to ensure that nutrition stays in the food supply chain.

What do you hope customers take away from your mission?

Renewal Mill is building a more sustainable food system by providing healthier food to more people using fewer resources. Our primary goal is to craft delicious food that customers love. After falling in love with the flavor, we hope that our customers also appreciate the environmental benefits associated with “full-cycle” food. We also want customers to know that as a public benefit corporation, Renewal Mill is committed to ensuring that all the work we do is good for the planet and our community.